Electrical Safety on Site – Why does the Good Ole’ Lead Get a Beating?

Talking about electrical safety in NSW

How many eyes rolling did I just imagine seeing after reading the headline? More than just a few, I’m sure.

“Not another lead to repair!” I can hear the electrician exclaim as it gets thrown through the site shed door, hitting the wall, and falling to the floor.

We all know, and especially those in the construction industry, that electrical safety is up there with falls from height, working around mobile powered plant and the other eighteen high risk construction work hazards, yet we don’t give it the priority it’s due.

According to Safework NSW, electrocution is the second leading cause of traumatic fatalities in construction in NSW (Source).

Electrical safety requirements

Where do we start when it comes to electrical safety legal requirements for your business, it’s employees and any sub-contractors that you may engage?

You may be surprised to know that very few electricians know what the requirements are, meaning many are at risk of non-compliance.

So it’s fair to say, its all starts with education and information.

In NSW the legal requirements are explained in the key safety legislation; NSW WHS Act 2011 and NSW Regulations 2017. More specifically, Part 4.7 General electrical safety in workplaces and energised electrical work.

Additional to the key legislation is the Code of Practice, Managing electrical risks.

Electrical safety considerations

The other day I had my electrician do some work at my office. I observed him during my conversation with a client on the phone and here’s what I observed.

The electrician had an apprentice with him who was unpacking the van with the gear requirements for the job. The supervisor was off to the side of the van getting the miscellaneous items but keeping an eye on the apprentice.

On the door of the van was a checklist (I noticed this after the client conversation when I was paying for the job) with the heading “Your safety is important – check, check, check!”

As they drove off, it got me thinking of what happens on the sites I visit. Does the message on the checklist run through the minds of those workers prior to them commencing work?

“Your safety is important – check, check, check!”

So, what do we need to consider when it comes to electrical safety on a construction site in NSW?

Information, training and awareness

The best time on a site to give the information, training and awareness to your team is during the conversation prior to the shift. The generic term is Prestart and or Toolbox Talk.

You can get help with this by engaging a qualified safety consultant to assist with the delivery of the training as well as helping your team understand key construction site risks and how to identify and mitigate them.

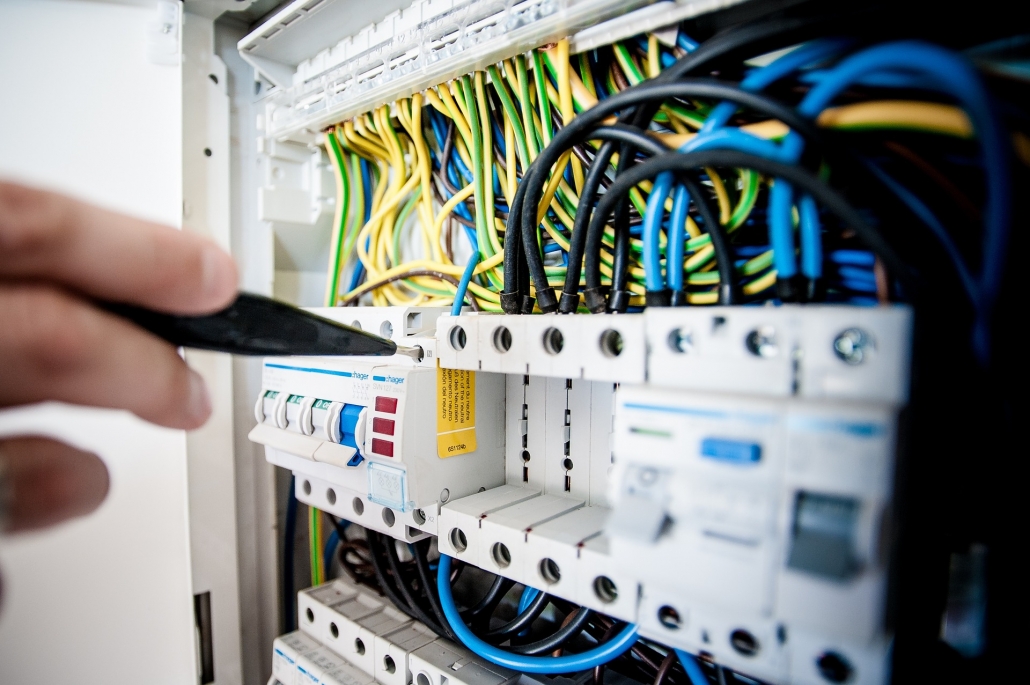

Test and tag

All electrical equipment must be tested and tagged and is generally done as per the requirements in the NSW WHS Regulations 2017. The period ranges between immediately for new leads and equipment to max three monthly.

Ancillary items

There are many ways to safely elevate leads off the surface which include lead stands, lead hooks to mention a few.

These are lightweight and easily moved from location to location on site.

Need help with electrical safety compliance for your business?

My name is Sean Brown and I am the founder of SMB Safety. In the industry for over 25 years, I help construction based businesses identify safety risks and mitigate them through better worksafe systems. The starting point is you and I having a no-obligation telephone call about your concerns and objectives. I can very quickly help you identify gaps and clear next steps forward.

Agreed, I see lots of equipment that is only domestically rated as well as damaged leads held together with duct tape on construction sites. Pre starts including checking all gear is a must, but to know what you’re looking for? I guess that’s another reason why WHS Advisors exist ? nice article Sean

Hi Laurence,

Thanks for taking the time to read my article.